Super Duplex | UNS S32760 | ASTM/ASME A240 / F55 | 1.4501

Excellent corrosion resistance against general corrosion, stress corrosion cracking, corrosion fatigue, pitting, crevice and erosion corrosion and possessing very high mechanical strength properties.

Good weldability, post weld heat treatment not necessary.

Max. Temperature for long periods of service: 280¡ãC (536¡ãF) / (300¡ãC/572¡ãF possible for short periods).

TECHNICAL INFO

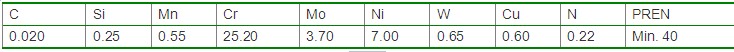

Chemical Composition (average %)

Hot Forming: Forging 1280 to 1000¡ãC (2336-1832¡ãF) Air cooling

Heat Treatment:Quenching:1100¡ãC (2012¡ãF) Water, air (thickness below 2mm) Structure as quenched:Weldability of super duplex 32760 is good. The welding procedures are similar to those applied for conventional duplex grades. Welding consumables for different welding methods are available.

The machine ability of super duplex 32760 is superior to comparable super duplex grades due to its optimized inclusion characteristic. Further details are available on request.

MECHANICAL PROPERTIES

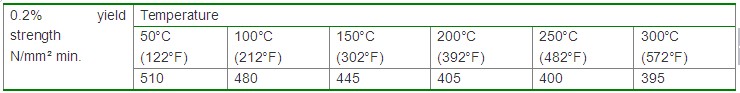

HIGHT TEMPERATURE PROPERTIES Condition: quenched